Estimated reading time: 18 minutes

Introduction

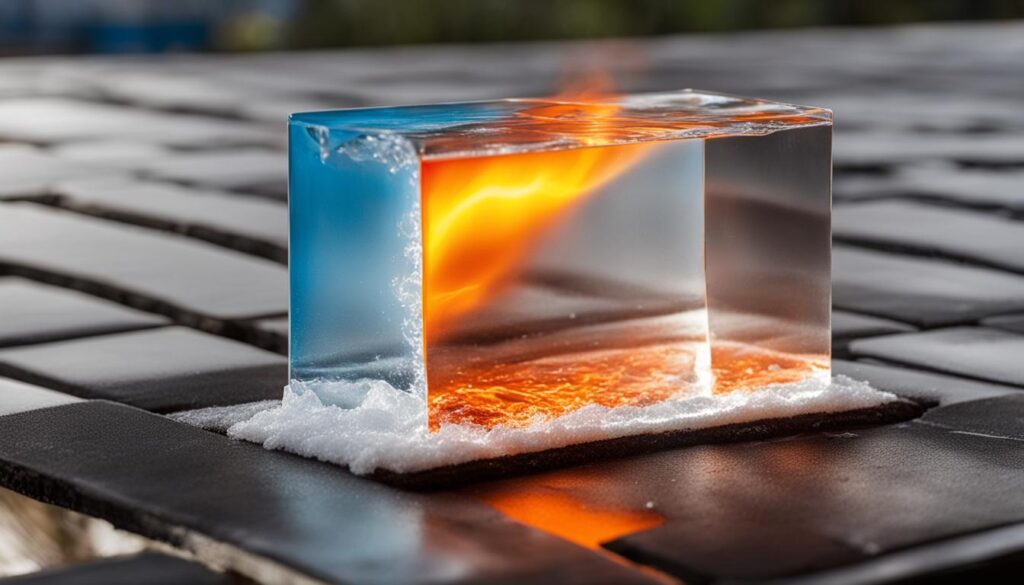

When evaluating if is plexiglass a good insulator, it’s crucial to examine the characteristics that distinguish this material in various environments. Since its introduction in 1928, plexiglass, also known by names like acrylic glass or lucite, has shown significant insulation capabilities against heat and cold, competing closely with traditional materials like glass. Its structure provides an effective barrier against temperature changes, making it an appealing choice for enhancing energy efficiency in buildings. The plexiglass r value, indicating its thermal resistance, highlights its effectiveness in stabilizing indoor temperatures, offering a comfortable setting without the high energy costs. This transparent thermoplastic surpasses glass in plexiglass vs glass insulation, demonstrating its ability to retain heat more efficiently and serving as a practical solution for plexiglass window insulation.

Plexiglass’s utility goes beyond thermal insulation. Its resistance to impact, referenced in terms like lexan bullet proof glass, indicates that windows crafted from this material provide improved security and durability, especially in locations subject to harsh weather. Furthermore, the simplicity with which plastic sheets or plexiglass panel can be fitted and shaped allows for varied applications across different sectors. From enabling light to pass through greenhouse panels to acting as a safeguard in security buildings, plexiglass proves to be a versatile option, unmatched by conventional insulating materials. Its transparency and robustness make it a prime choice for plexiglass window insulation, aiming not just to insulate but also to allow natural illumination into spaces without compromising safety or efficiency. Opting for acrylic sheet as a core material can lead to significant energy savings and a lower environmental impact, aligning with contemporary demands for sustainability and durability.

Key Takeaways

- Plexiglass is a transparent thermoplastic material that has been used since 1928 for various applications.

- Plexiglass is a good insulator against both heat and cold, holding heat better than glass and providing energy-efficient insulation.

- Plexiglass windows offer 10 times greater impact resistance than glass, making them suitable for areas prone to harsh weather conditions.

- Plexiglass can be easily insulated using foam tape, weather stripping, and frame securing.

- Plexiglass is a practical choice for insulation, offering thermal insulation, durability, and energy efficiency.

Benefits of Using Plexiglass Windows

Choosing plexiglass windows provides several advantages, positioning them as a superior alternative to traditional glass options. Plexiglas®, a form of acrylic plastic, stands out for its highly durable nature and easy to install feature, offering clear benefits over more conventional choices. A key attribute is its capability to be cut to size, ensuring versatility across various applications, including windows and canopies. Unlike glass, plexiglass holds up better against impacts and environmental changes, meaning cold will find its way through less effectively, thereby improving thermal efficiency within residential and commercial settings.

Additionally, Plexiglas has a higher lambda value means it’s perceived to conduct more heat and thus, yet when installed correctly, it still acts as an effective barrier against temperature transfer, disputing the idea that a material can conduct more heat automatically diminishes its insulative qualities. Its non-glare feature is particularly beneficial in areas where minimizing reflection is essential, improving visibility and overall comfort. Furthermore, plexiglass comes in a variety of styles and finishes, allowing for design flexibility that can replace glass in many scenarios. Being a polymer, the sheets effectively function as windows, merging practicality with visual appeal.

Here are some key advantages:

1. Energy savings: Plexiglass windows are highly efficient in holding heat, making them a great option for saving energy and reducing heating costs. Their superior thermal insulation properties help maintain a comfortable temperature inside the house, regardless of the weather conditions outside.

2. Durability and impact resistance: Plexiglass windows are 10 times stronger than traditional glass, making them highly impact-resistant and less likely to break. This durability makes them a reliable option, especially in areas prone to storms and harsh weather conditions.

3. Easy installation: Plexiglass is easy to cut and install, allowing for a hassle-free installation process. Homeowners can easily customize the windows to fit their specific needs, making plexiglass windows a versatile option for any home.

4. Better light transmission: Plexiglass windows transmit light better than standard glass, allowing more natural light to enter the home. This enhances the aesthetic appeal of the space and reduces the need for artificial lighting during the day, resulting in additional energy savings.

With these benefits, it is clear why plexiglass windows are becoming popular for homeowners looking to enhance insulation and save on energy costs.

Comparison of Plexiglass and Glass Windows

| Features | Plexiglass Windows | Glass Windows |

|---|---|---|

| Thermal Insulation | Superior thermal insulation properties | Lower thermal insulation compared to plexiglass |

| Impact Resistance | 10 times stronger than glass | More prone to breakage |

| Customization | Easy to cut and install in various shapes and sizes | Limited customization options |

| Light Transmission | Allows better light transmission | May restrict natural light |

As the table above illustrates, plexiglass windows outperform traditional glass windows in insulation, impact resistance, customization options, and light transmission. These advantages make plexiglass an optimal choice for homeowners who value energy efficiency and durability.

Insulating Poly(methyl methacrylate) Windows for Heating, ventilation, and air conditioning

Using Poly(methyl methacrylate) (PMMA) windows, often known as plexiglass, for heating, ventilation, and air conditioning offers numerous advantages in homes and businesses. Queries like does plexiglass insulate are common; indeed, plexiglass alongside its counterparts acrylic and perspex, serve as excellent insulators. These materials excel in retaining warmth during the cold season, positioning them as prime choices for energy-efficient constructions. Contrary to traditional glass, plexiglass is more resistant to damage and less likely to crack or shatter, making it a preferred option for do-it-yourselfers and experts.

It’s advisable to recommend ordering a sample piece to practice different machining styles, maximizing the use of the material’s flexibility to meet your project’s requirements accurately. At ShapesPlastics, we maintain a large inventory of popular brands across a variety of thicknesses, ensuring you get the thickness you need for your endeavor. Whether the material used for your application depends entirely on factors like thermal insulation, durability, or aesthetic appeal, contact us for a comprehensive look at our vast selection to find an ideal match for your HVAC project needs.

| Insulation Steps for Plexiglass Windows |

|---|

| 1. Apply foam tape weather stripping to fill gaps around the window frame. |

| 2. Screw the frame onto the window to ensure a tight fit. |

| 3. Use silicone caulk to create a seal on the outside edge of the frame. |

| 4. Consider using multiple layers of weather stripping for added insulation. |

| 5. Apply an anti-static cleaner to the back of the plexiglass. |

By following these insulation techniques, you can enhance the efficiency of plexiglass windows, reducing heat transfer and improving energy savings. Whether for residential or commercial use, properly insulating plexiglass windows is a practical and cost-effective way to create a more comfortable and energy-efficient living or working environment.

Plexiglass Window Use-Cases

When considering Plexiglass Window Use-Cases, it’s evident that this material stands out for its insulation qualities. Many inquire whether is acrylic a good insulator or is acrylic a good thermal insulator, and the response is undoubtedly affirmative. Acrylic, commonly referred to as plexiglass or perspex, is acclaimed for its insulation efficiency, crucial for both homes and business premises. The r value of plexiglass highlights its effectiveness in reducing energy exchange, positioning it as an ideal selection for enhancing a building’s energy conservation.

The method of placing plexiglass over windows showcases its sturdiness and insulation capacity. Both homeowners and businesses gain from the r value of plexiglass, leading to decreased expenses on heating and cooling. This attribute, along with its impact resistance and simplicity in fitting, positions plexiglass as a more favorable choice compared to conventional glass. Whether questioning is perspex a good insulator or the general efficiency of plexiglass in thermal retention, the outcome is straightforward. Plexiglass delivers a dependable and economically efficient solution for numerous uses.

Greenhouse Panels and Skylights

Greenhouse Panels and Skylights made from Poly(methyl methacrylate) (PMMA), widely recognized as Plexiglass, are revolutionizing how we approach building insulation material and natural lighting as an insulator solution. This plastic stands out for its exceptional transparency and translucency, allowing maximum solar gain to penetrate, vital for plant growth in greenhouses and enhancing natural light in skylights.

Unlike tempered glass or polyvinyl chloride, Plexiglass boasts a higher R-value (insulation), making it more efficient at retaining heat, crucial for maintaining optimal temperatures in greenhouses, measured in Kelvin, and reducing energy consumption in buildings. Its dielectric properties minimize interference with antenna (radio) signals, ensuring that antenna feeds operate without disruption.

Additionally, its durability against heat and snow, coupled with the ability to integrate solar cells for solar thermal energy collection, offers a sustainable and energy-efficient solution. The use of aerogel or vermiculite as supplementary insulation can further enhance its performance, making Plexiglass an ideal choice for glazing (window) applications where ductility and resilience are paramount.

Solar Panels

Solar Panels crafted from Plexiglass are transforming the realm of renewable energy, thanks to their durability and exceptional light transmission insulator capabilities. This material’s resilience against harsh environmental conditions, from scorching heatwaves to freezing blizzards, ensures that solar cells embedded within these panels are protected and can operate at peak efficiency year-round.

The innate clarity of Plexiglass permits an abundance of sunlight to reach the solar cells, thereby maximizing energy efficiency in the conversion of sunlight to electricity. This is particularly important as the relative permittivity of Plexiglass, a measure of its ability to store electrical energy in an electric field, plays a crucial role in enhancing the overall performance of solar panels.

Unlike traditional materials that might corrode or degrade under intense solar exposure, the non-metallic nature of Plexiglass prevents such deterioration, ensuring a longer lifespan for solar panels. Furthermore, its compatibility with antenna feeds in solar farms amplifies its utility, making Plexiglass an indispensable material in the pursuit of sustainable and efficient energy solutions.

Security Buildings and High-level Security Facilities

Security Buildings and High-level Security Facilities increasingly rely on Plexiglass as a pivotal component in their design due to its exceptional durability and impact resistance. In environments where safety and security are paramount, Plexiglass stands out not just as a physical barrier, but also as an effective plexiglass insulator, contributing to the controlled climate within these sensitive areas. Its robustness against forceful impacts ensures that it can withstand attempts at breakage or vandalism, thus maintaining the integrity of the facility.

Moreover, its clarity does not compromise visibility, ensuring surveillance and monitoring are not hindered. This blend of transparency with toughness makes Plexiglass an indispensable material in the architectural and security planning of facilities that safeguard critical infrastructure or sensitive information. Opting for Plexiglass in constructing or retrofitting security buildings and high-level facilities underscores a commitment to leveraging advanced materials for enhanced protection and operational efficiency.

Retail Signage and Displays

In the world of retail signage and displays, the use of plexiglass shines for its adaptability and strength. Different from ordinary glass, plexiglass not just holds up better but is much more durable, marking it as a superior choice for both commercial and residential windows. Its insulating ability, often questioned as is plexiglass insulated, shows that its lambda value means the material is less likely to conduct more heat, a key factor in lowering energy bills. For tailored projects, cut-to-size plastic services are offered, where items priced incorporate the plus cutting fee, guaranteeing you receive the precise piece of the plastic sheet or a sample piece of the plastic for verification. This customization enables businesses to produce distinctive, striking signage and displays that attract attention without increasing indoor heat way into your house either. The selection of plexiglass provided gives multiple options in thickness per square foot, making plexiglass not just a functional but also an attractive option for all kinds of displays. Moreover, acrylic provides clear visibility that improves the display quality of products, reaffirming why plexiglass is also a favored material in the sector.

| Use-Case | Benefits |

|---|---|

| Greenhouse Panels and Skylights | Tolerant to heat and snow, allows natural light |

| Solar Panels | Can withstand extreme weather, maximizes energy efficiency |

| Security Buildings and High-level Security Facilities | Durable and impact-resistant |

| Retail Signage and Displays | Glass-like clarity, shatter-resistant |

As evident from the diverse applications mentioned above, plexiglass offers many benefits beyond traditional windows. Its properties make it suitable for various industries, enhancing functionality, durability, and visual appeal.

Plexiglass vs. Glass: A Comparison for Window Insulation

In the debate of Plexiglass vs. Glass: A Comparison for Window Insulation, Plexiglass emerges as a formidable contender, boasting a multitude of advantages that make it a preferred choice for many. With its inherently lower thermal conductivity, Plexiglass outshines traditional glass, positioning itself as a superior plexiglass insulator.

This characteristic significantly enhances a building’s energy efficiency by minimizing heat transfer, thereby maintaining a stable indoor temperature and potentially reducing reliance on heating and cooling systems. Beyond its insulating prowess, Plexiglass’s durability is noteworthy; it is 17 times stronger than glass, greatly reducing the risk of shattering upon impact.

This durability, combined with its lighter weight, simplifies transportation and installation processes. Moreover, Plexiglass’s versatility extends to aesthetics and functionality—it is available in a variety of colors, offers improved light transmission, and can be easily customized into unique designs. These attributes underscore the practical and economic benefits of choosing Plexiglass over glass for window insulation, making it an optimal choice for both residential and commercial applications seeking to enhance comfort, safety, and energy efficiency.

Benefits of Plexiglass Insulation:

- Lower thermal conductivity compared to glass

- 17 times stronger than glass

- It does not shatter easily.

- Lightweight and easy to transport

- Available in various colors

- Better light transmission

- Easier to cut and shape into custom designs

Furthermore, plexiglass windows offer improved impact resistance, making them ideal for areas prone to severe weather conditions. They can withstand strong winds, heavy rains, and even hail, providing added security and durability.

In summary, plexiglass is a reliable and efficient thermal insulator for window applications. Its lower thermal conductivity, strength, and versatility make it a preferred choice for homeowners and commercial building owners.

How to Install Plexiglass Sheets on Windows

Installing plexiglass sheets on windows is a simple process that can be done with a few basic steps. Here’s a step-by-step guide on how to install plexiglass sheets on windows:

Materials needed:

- Plexiglass sheets

- Steel framing pieces

- Screws

- Edging pieces

- Welding solvent

- Measure the height of the window frame: Using a tape measure, measure the height of the window frame from top to bottom. This measurement will determine the height of the steel framing pieces.

- Cut the steel framing pieces: Using a saw, cut the steel framing pieces to match the height of the window frame. Ensure that the pieces are cut accurately for a proper fit.

- Place the framing pieces inside the frame: Insert the steel framing pieces inside the window frame and secure them with screws. This will create a sturdy frame for the plexiglass sheets.

- Measure the lengths between the framing strips: Measure the lengths between the framing strips at the top and bottom of the window. This measurement will determine the width of the plexiglass sheets.

- Cut the frames to the appropriate lengths: Cut the frames according to the measured lengths. Ensure that the frames fit securely within the window frame.

- Position the cut-out pieces in the frame: Place them in the frame and screw them into place. This will secure the frame and prevent any movement or looseness.

- Cut the plexiglass sheet: Measure and cut the plexiglass sheet to the appropriate measurements using a saw or a plexiglass cutter. Ensure that the sheet fits perfectly within the frame.

- Attach the plexiglass sheet to the frame: Use edging pieces and welding solvent to attach the plexiglass sheet to the frame. Apply the solvent to the edges of the sheet and place the edging pieces on top to secure it.

- Remove the protective film: Carefully remove the protective film from the panel once the plexiglass sheet is securely attached to the frame. This will reveal the clear, transparent surface of the plexiglass.

- Reinstall the panel in the window frame: Finally, reinstall the panel with the plexiglass sheet back into the window frame. Ensure that it fits snugly and securely.

By following these steps, you can successfully install plexiglass sheets on windows. Whether you’re looking to enhance insulation in your building or create a durable and weather-resistant window, plexiglass is a reliable and versatile material to consider.

Temperature Resistance of Plexiglass

The Temperature Resistance of Plexiglass is a standout feature that underscores its utility across a spectrum of applications, particularly in scenarios demanding high durability against climatic variances. This thermoplastic, also recognized as acrylic, exhibits remarkable resilience, capable of enduring a wide temperature range from as chilly as minus 40 degrees Celsius to a warm 70 to 80 degrees Celsius.

Such an attribute not only earmarks Plexiglass as an exceptional plexiglass insulator but also accentuates its suitability for outdoor settings — be it the protective covering for greenhouses that bask under the sun or the vibrant illuminated advertising signs that face the elements. Its formidable resistance to temperature extremes ensures that Plexiglass retains its structural integrity and visual clarity, irrespective of the environmental conditions. This resilience, combined with its insulating properties, renders Plexiglass an indispensable material for projects that require a blend of durability, clarity, and energy efficiency.

Comparative Temperature Resistance

| Plexiglass Type | Low-Temperature Limit (°C) | High Temperature Limit (°C) |

|---|---|---|

| Standard Plexiglass | -40 | 70-80 |

| High-Temperature Plexiglass | -40 | 100-120 |

| Heat-Resistant Plexiglass | -40 | 150-170 |

The table above showcases the temperature limits for different types of plexiglass. While standard plexiglass performs well in most applications, high-temperature and heat-resistant plexiglass variants offer even greater resilience in extreme conditions. These specialized types of plexiglass can withstand higher temperatures without compromising their structural integrity or optical properties.

When utilizing plexiglass in temperature-sensitive applications, it’s essential to consider factors such as thermal expansion and contraction. Plexiglass expands and contracts with temperature changes, so this movement must be allowed during installation to prevent warping or cracking. Consulting with a professional installer or following manufacturer guidelines can help ensure proper installation and maximize the longevity of plexiglass in various temperature environments.

Considerations for Plexiglass Expansion

When using plexiglass as an insulating material, it’s crucial to consider its thermal properties and the potential for expansion and contraction with temperature changes. Unlike glass, plexiglass expands and contracts significantly, and this behavior must be considered during installation to ensure a proper fit and avoid any potential issues.

Understanding Plexiglass Expansion

Understanding Plexiglass Expansion is crucial for anyone utilizing this material in their projects, especially considering its role as a plexiglass insulator. Plexiglass, known for its versatility and durability, is subject to thermal expansion and contraction—a phenomenon where it enlarges with heat and shrinks with cold. While highlighting the material’s adaptability to varying temperatures, this characteristic also necessitates careful planning in installation processes to mitigate potential stress and damage.

Ensuring sufficient space for this expansion and contraction can prevent the occurrence of cracks or structural compromises, maintaining the integrity of installations. Properly accounting for Plexiglass’s coefficient of expansion is not just about safeguarding the material but also protecting the surrounding framework and ensuring longevity. This attention to detail ensures that Plexiglass continues to serve as an effective insulator and durable option for various applications, from architectural features to protective barriers, without succumbing to the adverse effects of temperature fluctuations.

“Plexiglass expands and contracts with temperature changes, and it is important to consider the allowance for expansion when using it for applications such as roofing.” – Plexiglass Installation Expert

Allowance for Expansion

In the context of utilizing Plexiglass, especially as a plexiglass insulator, the concept of Allowance for Expansion is paramount for ensuring the material’s durability and the structural integrity of the installation. Given Plexiglass’s inherent nature to expand and contract in response to temperature changes, allocating a specific amount of space—typically between 5 to 6 millimeters per linear meter of the sheet—is essential to accommodate these fluctuations.

This precautionary measure prevents the exertion of undue stress on the Plexiglass and the surrounding framework, averting potential cracks or damage that could compromise the installation’s effectiveness and longevity. Such an allowance enables Plexiglass to perform optimally as an insulator, maintaining its clarity and structural integrity over time. Ensuring there is sufficient room for this thermal expansion is not just about safeguarding the material; it’s about preserving the overall functionality and aesthetic appeal of the Plexiglass application, whether it be in windows, skylights, or other architectural elements.

| Temperature | Plexiglass Length |

|---|---|

| 20°C | 1000mm |

| 45°C | 1005mm (Expansion of 5mm) |

| 0°C | 995mm (Contraction of 5mm) |

By providing the necessary allowance for expansion, you can ensure that the plexiglass remains structurally sound and avoids any issues caused by thermal stress. This consideration is particularly important for applications such as roofing, where changes in temperature can be more significant and frequent.

It’s important to consult with professionals experienced in working with plexiglass installations to ensure that the appropriate allowance for expansion is made and that the material is properly installed to withstand temperature fluctuations over time.

Frequently Asked Questions

Yes, Plexiglass, also known as acrylic, is a good insulator against heat and cold. It has lower thermal conductivity than regular glass and offers better insulation properties.

Plexiglass windows provide numerous benefits for insulation, including their strength, durability, and reliability, especially during storms. They are also easy to cut and install, transmit light better than glass, and offer 10 times more impact resistance.

You can insulate Plexiglass windows by using foam tape weather stripping to fill gaps around the window frame, screwing the frame onto the window for a secure fit, and applying silicone caulk to create a seal. Other techniques such as using multiple layers of weather stripping and adding an anti-static cleaner to the back of the Plexiglass can further enhance insulation efficiency.

Plexiglass windows are widely used in various applications such as greenhouse panels, skylights, solar panels, security buildings, high-level security facilities, and retail signage and displays. They offer durability, clarity, and resistance to extreme weather conditions.

Plexiglass has better insulating properties than glass due to its lower thermal conductivity. Although glass is a better insulating material, Plexiglass compensates with its other benefits such as strength, impact resistance, lighter weight, better light transmission, and ease of cutting and shaping into custom designs.

Installing Plexiglass sheets on windows is a straightforward process. It involves measuring the window frame, cutting and securing steel framing pieces, measuring the lengths between the framing strips, positioning and screwing the cut-out pieces, and attaching the Plexiglass sheet to the frame using edging pieces and welding solvent. The final step is removing the protective film and reinstalling the panel in the window frame.

Plexiglass is highly resistant to extreme temperatures. It can withstand temperatures as low as minus 40 degrees Celsius and can be used in temperatures up to about 70 to 80 degrees Celsius, depending on the specific type of Plexiglass. It begins to fuse at around 200 degrees Celsius.

Plexiglass expands and contracts with temperature changes, so it’s important to consider the allowance for expansion when using it for applications such as roofing. Typically, the allowance for expansion is about 5 to 6 millimeters per linear meter of sheet.

Conclusion

In conclusion, the question of whether Plexiglass is a good insulator against heat and cold has been thoroughly examined, revealing its significant advantages over traditional glass and other materials. Poly(methyl methacrylate), or Plexiglass, stands out for its superior thermal insulation properties, making it an ideal choice for heating, ventilation, and air conditioning (HVAC) systems. Its ability to retain heat, coupled with a high R-value (insulation), ensures that it offers excellent protection against temperature fluctuations. This characteristic, along with its resistance to ultraviolet (UV) light and impact, positions Plexiglass as a versatile and durable solution for windows and other architectural needs. Compared to polycarbonate and polystyrene, Plexiglass provides a better balance of light transmission, insulation, and durability, making it a preferred material for enhancing energy efficiency in homes and commercial buildings alike.

Furthermore, the practical applications of Plexiglass extend beyond simple window insulation. Its use in greenhouse panels, skylights, solar panels, and security facilities underscores the material’s adaptability and effectiveness in a variety of settings. The process of insulating Plexiglass windows, involving foam tape weather stripping and silicone caulk, further amplifies its insulating capabilities, ensuring a snug fit that minimizes heat transfer. As environmental considerations and energy efficiency become increasingly important, the choice of materials like Plexiglass becomes pivotal. Its ability to withstand extreme temperatures, coupled with the considerations for expansion and contraction, showcases the need for a meticulous approach to installation, ensuring longevity and performance. By opting for Plexiglass, homeowners and architects not only invest in a material that offers superior insulation and durability but also contribute to a sustainable future, making it clear that Plexiglass is indeed a good insulator for both residential and commercial applications.

James Dunnington leads the James Dunnington Collection, featuring five unique blogs: a practical Pet Care Guide, an enlightening Ancient History Blog, a resourceful Home Improvement Guide, a cutting-edge Tech Innovation Guide, and a strategic Online Money Making platform. Each site delivers valuable insights designed to empower and inform. For updates and more tips, visit our Contact Us page to sign up for our newsletter, ensuring you never miss out on the latest content from any of these dynamic fields.